忠縣橡膠止水帶接頭采用冷粘法與熱粘法哪個(gè)更好些?

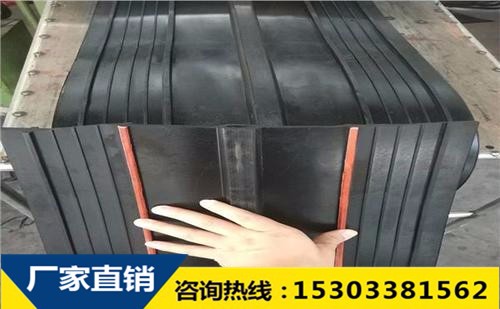

橡膠止水帶接頭采用冷粘法與熱粘法哪個(gè)更好些?衡水融通橡膠制品有限公司全心全意為您服務(wù)每!橡膠止水帶施工中由于襯砌長(zhǎng)度等結(jié)構(gòu)尺寸和形式不同,而橡膠止水帶又都有一定的長(zhǎng)度規(guī)格,現(xiàn)場(chǎng)使用時(shí),不可避免的會(huì)出現(xiàn)止水帶接頭情況。以往止水帶接頭通常采用冷粘法,傳統(tǒng)的冷粘法是將橡膠止水帶兩個(gè)接頭處的膠梗削平,然后進(jìn)行打毛處理,完畢后涂一層膠粘劑,為了增強(qiáng)效果,待其晾干后再涂一層,然后將兩個(gè)接頭放置在預(yù)定位置進(jìn)行膠粘,并進(jìn)行加壓后澆筑混凝土。還有一種接頭方法就是用的橡膠接頭模具,經(jīng)過(guò)加溫?zé)崃蚧姆绞浇宇^。

In the construction of rubber water stop belt, because of the different lining length and other structural dimensions and forms, the rubber water stop belt has certain length specifications. When used in the field, the joint of the water stop belt will inevitably occur. In the past, the joint of water stop tape was usually made by cold bonding method. The traditional cold bonding method is to flatten the rubber stem at the two joints of the rubber water stop tape, then to wool it, and then coat it with an adhesive layer after finishing. In order to enhance the effect, the joint is dried and then coated with another layer. Then the two joints are placed in a predetermined position for bonding, and finally concrete is poured under pressure. Another joint method is to use a professional rubber joint mold, after heating and vulcanization of the way joints.

橡膠止水帶熱硫化焊接的基本工藝是在兩條橡膠止水帶搭接處放入止水帶焊接專用生膠片,控制溫度、時(shí)間,用硫化焊接機(jī)進(jìn)行焊接,焊接機(jī)對(duì)止水帶搭接接頭進(jìn)行加熱加壓,使位于兩個(gè)止水帶接頭之間的生膠片熔化,生膠片與橡膠止水帶接頭處的硫化膠材料相似,親和作用力大,生膠片里的硫化劑擴(kuò)散至接觸界面與硫化膠內(nèi)剩余的雙鍵發(fā)生交聯(lián)反應(yīng),形成共硫化體系,使接頭處連為一體。再通過(guò)足夠的擠壓力,實(shí)現(xiàn)兩條止水帶之間的緊密粘接,從而達(dá)到橡膠止水帶熱硫化焊接防水的要求。

橡膠止水帶熱硫化焊接工藝流程施工方法:橡膠止水帶端頭切割整齊并打磨平整,上下對(duì)正→在止水帶接縫位置放置止水帶專用生膠片(寬10cm,長(zhǎng)35cm)→用手將接縫處生膠片壓實(shí)密貼→接通電源,對(duì)焊機(jī)進(jìn)行預(yù)熱→將止水帶平鋪在焊機(jī)底板上,位置對(duì)正→夾緊模具,用手輪進(jìn)行鎖緊→接通熱硫化焊機(jī),溫度調(diào)整至145℃→將加熱時(shí)間調(diào)整為10分鐘,冷卻時(shí)間調(diào)整為8分鐘至指示燈亮起→關(guān)閉電源→對(duì)止水帶焊接質(zhì)量進(jìn)行檢查,合格后進(jìn)行止水帶安裝。

在進(jìn)行止水帶焊接工作前應(yīng)做好準(zhǔn)備工作,工作場(chǎng)地應(yīng)清除現(xiàn)場(chǎng)易燃易爆物品、強(qiáng)熱源、油類或強(qiáng)烈氧化作用溶劑等,保持場(chǎng)地整潔。準(zhǔn)備好磨光機(jī)及焊接設(shè)備,將控制電箱與焊接模具進(jìn)行連接,再將焊接模具打開(kāi),上下兩面均勻涂刷機(jī)油,防止機(jī)具在高溫條件下與止水帶粘結(jié)。將兩條止水帶接頭切割整齊,用磨光機(jī)將需要焊接的兩個(gè)接頭上的膠梗及污漬全部打磨,使止水帶粘合面平整且無(wú)污漬。縱向打磨長(zhǎng)度為10~15cm。

橡膠止水帶熱硫化焊接時(shí)間短、效率高,全程自動(dòng)化,非常方便。事先接通電源,對(duì)焊機(jī)進(jìn)行預(yù)熱,預(yù)熱的溫度沒(méi)有固定的,可根據(jù)現(xiàn)場(chǎng)氣溫的高低以及施工條件來(lái)定,一般的情況下預(yù)熱不超過(guò)20分鐘。先將一條止水帶接頭放入熱熔模具中,使其打磨面朝上水平放置,取出專用生膠片(生膠片是隨焊機(jī)一起購(gòu)買(mǎi)配置),生膠片長(zhǎng)約35cm,寬10cm,將其粘在止水帶上,然后將另一條止水帶打磨面朝下放置,位置對(duì)正,與條止水帶搭接長(zhǎng)度不小于10cm,用手將止水帶與生膠片壓實(shí)密貼,夾緊模具,并用手輪鎖緊。在熱硫化焊機(jī)溫度控制箱的溫度調(diào)節(jié)器上將熱硫化焊機(jī)加熱溫度調(diào)為145℃,將加熱時(shí)間調(diào)整到10分鐘左右,將冷卻固化時(shí)間調(diào)整到8分鐘左右。

| 分享此文章: |

“相關(guān)閱讀”

- 忠縣外貼式橡膠止水帶施工注意事項(xiàng)有哪些?…

- 忠縣氯丁橡膠止水帶應(yīng)用于哪些方面?…

- 忠縣橡膠止水帶現(xiàn)場(chǎng)安裝關(guān)鍵步驟及常見(jiàn)問(wèn)題有哪些?…

- 忠縣橡膠止水帶651型多少錢(qián)一米?…

- 忠縣橡膠止水帶的施工過(guò)程其實(shí)并不復(fù)雜…

- 忠縣橡膠止水帶的正確接法?橡膠止水帶搭接方法?…

- 忠縣劃重點(diǎn)!著重強(qiáng)調(diào)!變形縫用橡膠止水帶材質(zhì)要求…

- 忠縣鋼板膩?zhàn)酉鹉z止水帶安裝時(shí)要著重注意哪幾個(gè)問(wèn)題?…

- 忠縣遇水膨脹橡膠止水帶施工工藝…

- 忠縣中埋式可注漿止水帶原理…

產(chǎn)品中心 Product Center

聯(lián)系電話:15303381562

聯(lián)系人:王經(jīng)理

QQ:249637288

地址:河北省衡水濱湖新區(qū)彭杜鄉(xiāng)西三景官二區(qū)38號(hào)